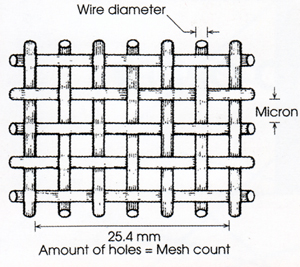

Woven Wire Mesh (Ex-Stock)

This is used extensively in various industries and different applications. These items are available ex-stock from 25mm down to 25 micron and are available in various types of weave and everything else can be manufactured.

Plain Weave Meshes

| Mesh Count per inch | Wire Diameter (mm) | Aperture Size (mm) | Open Area | Weight for Stainless Steel (kg/sq m) |

| 5 | 1.000 | 4.080 | 65% | 2.48 |

| 6 | 0.900 | 3.333 | 62% | 2.41 |

| 8 | 0.900 | 2.275 | 51% | 3.22 |

| 8 | 0.710 | 2.465 | 60% | 2.00 |

| 10 | 0.900 | 1.640 | 42% | 4.02 |

| 10 | 0.710 | 1.830 | 52% | 2.50 |

| 10 | 0.500 | 2.040 | 65% | 1.24 |

| 12 | 0.560 | 1.557 | 54% | 1.87 |

| 14 | 0.560 | 1.254 | 48% | 2.18 |

| 16 | 0.560 | 1.028 | 42% | 2.49 |

| 16 | 0.500 | 1.088 | 47% | 1.99 |

| 16 | 0.450 | 1.138 | 51% | 1.61 |

| 16 | 0.315 | 1.273 | 64% | 0.79 |

| 20 | 0.500 | 0.770 | 37% | 2.48 |

| 20 | 0.450 | 0.820 | 42% | 2.01 |

| 20 | 0.355 | 0.915 | 52% | 1.25 |

| 24 | 0.355 | 0.703 | 44% | 1.50 |

| 28 | 0.315 | 0.592 | 43% | 1.38 |

| 30 | 0.315 | 0.532 | 39% | 1.48 |

| 30 | 0.280 | 0.567 | 45% | 1.17 |

| 36 | 0.250 | 0.456 | 42% | 1.12 |

| 40 | 0.224 | 0.411 | 42% | 1.00 |

| 50 | 0.210 | 0.298 | 34% | 1.10 |

| 50 | 0.190 | 0.318 | 39% | 0.90 |

| 60 | 0.200 | 0.22 | 28% | 1.23 |

| 60 | 0.180 | 0.243 | 33% | 0.97 |

| 70 | 0.150 | 0.231 | 34% | 0.78 |

| 80 | 0.125 | 0.193 | 37% | 0.62 |

| 100 | 0.112 | 0.142 | 31% | 0.62 |

| 120 | 0.090 | 0.122 | 33% | 0.48 |

| 120 | 0.080 | 0.132 | 39% | 0.38 |

| 150 | 0.060 | 0.109 | 42% | 0.27 |

| 165 | 0.050 | 0.104 | 46% | 0.20 |

| 180 | 0.050 | 0.091 | 42% | 0.22 |

| 200 | 0.050 | 0.077 | 37% | 0.25 |

| 200 | 0.040 | 0.087 | 47% | 0.16 |

| 250 | 0.040 | 0.062 | 37% | 0.20 |

| 300 | 0.036 | 0.055 | 42% | 0.13 |

| 325 | 0.036 | 0.042 | 29% | 0.21 |

| 400 | 0.028 | 0.035 | 28% | 0.18 |

| 500 | 0.025 | 0.026 | 26% | 0.16 |

Hollander Weave Meshes

Nominal Mesh Count per inch

|

Wire Diameter

|

Particle Retention (micron) |

Porosity | Thickness (mm) |

Weight for Stainless Steel (kg/sq.m) |

||||||

| 12 | 70 | 0.600 | 0.400 | 300 | 62% | 1.225 | 3.64 | ||||

| 24 | 110 | 0.355 | 0.250 | 120 | 60% | 0.710 | 2.70 | ||||

| 50 | 250 | 0.140 | 0.112 | 60 | 59% | 0.315 | 1.00 | ||||

Types of Weave

|

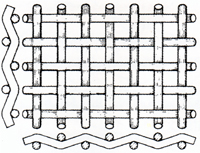

Plain Weave:

The most commonly used weave. Each weft wire passes alternatively over and under each warp wire and vice versa. Warp and weft wire diameters are generally the same. Plain weave meshes are available with apertures from 10.7mm (2 mesh) to 0.05mm (325 mesh) |

|

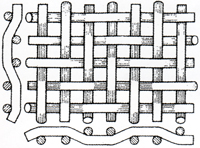

Twill Weave:

Stronger than Plain Weave. Each weft wire alternativel crosses over two, then under two warp wires, producing a diagonal pattern. The wire diameter for both warp and weft is normally the same. Twill weave is usually used to accomodate heavier than standard wire diameter is association with a given mesh. Specifications finer than 300 are normally twill woven. |

|

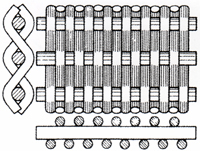

Hollander Weave:

A Plain Weave with the warp wires of larger diameter than the weft. The weave is made up of a limited number of warp wires interwoven with the maximum number of weft wires which can be knocked up. This is strong and firm and is most frequently used for high pressure filtration. |

Specifications Required To Order

|

|

Other Products:

- Tubular Filters

- Rimmed Screen Packs

- Tensioned Screen

- Woven Wire Screens

- Perforated Plate

- Expanded Metal

- Welded Mesh